From Norway we got the following message and some great pictures.

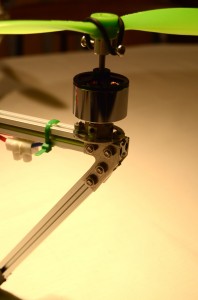

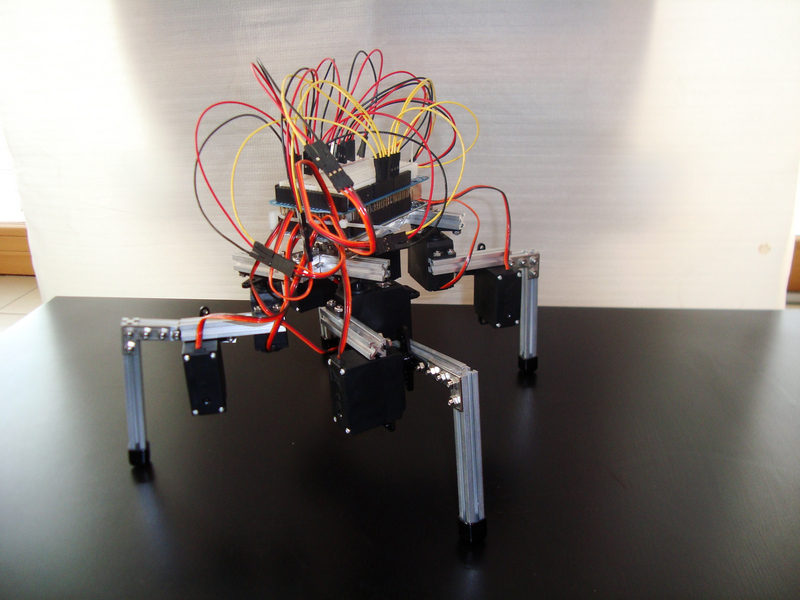

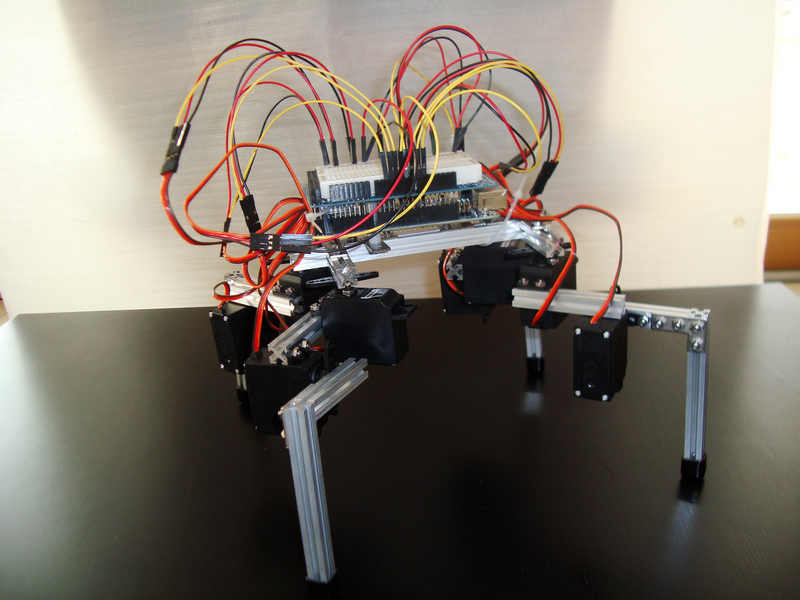

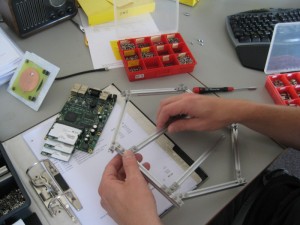

Just thought I’d send you some photos of a quadcopter I and a friend built recently, using MakerBeam aluminum profiles. We used 4×30 cm long beams to make the arms, and mounted a plexiglas plate and a plastic box on top, to hold the RC receiver and the controller card. Beneath the plate we made a battery mount, and fastened all the wires using zip ties. We also modified the motor mounts so that they could be screwed directly onto the beams.

I all, I find that MakerBeam is very easy to use, and it is also very easy to be creative and modify different designs. Great! However, I have some suggestions for additional features:

– The starter kit could come with a set of longer M3 screws, to make it easier to mount “external elements” (not MakerBeams)

– It would be nice to introduce some kind of “joint”, so that one beam could rotate relative to the other. A combination with some kind of spring would be nice. For example, in our quadcopter this could be used to introduce spring damping on the legs.

Hope you like the pictures, and good luck with further development,

—

Martin

We think it looks great! Thank you Martin.

If you have pictures, videos or suggestion for MakerBeam please let us know!!

Team MakerBeam.eu