The corner cubes arrived yesterday (May 15), late in the afternoon. While I was excited, made a few packages and started emailing customers, Johan tested some cubes and was not entirely pleased. What he discovered is that micrometers matter.

It looked like the special countersunk bolts did not sink as deep in the cube as should. First there was a sense of disbelief. The corner cubes are from the same manufacturer where we ordered our first batch from. Only for this batch we opted to have the cubes anodised.

Then we thought it maybe was a flawed screw. The particular screw used in that instance had an extra rim as Johan noticed. Other screws in the pack looked fine and tested fine, or did they?

Using a hex key driver and some force they looked okay. At that point we did not know whether it was this flawed screw or whether these cubes are different. Ever so slightly different and with the naked eye hard to identify. Especially in a hurry since I wanted to ship out backorders!

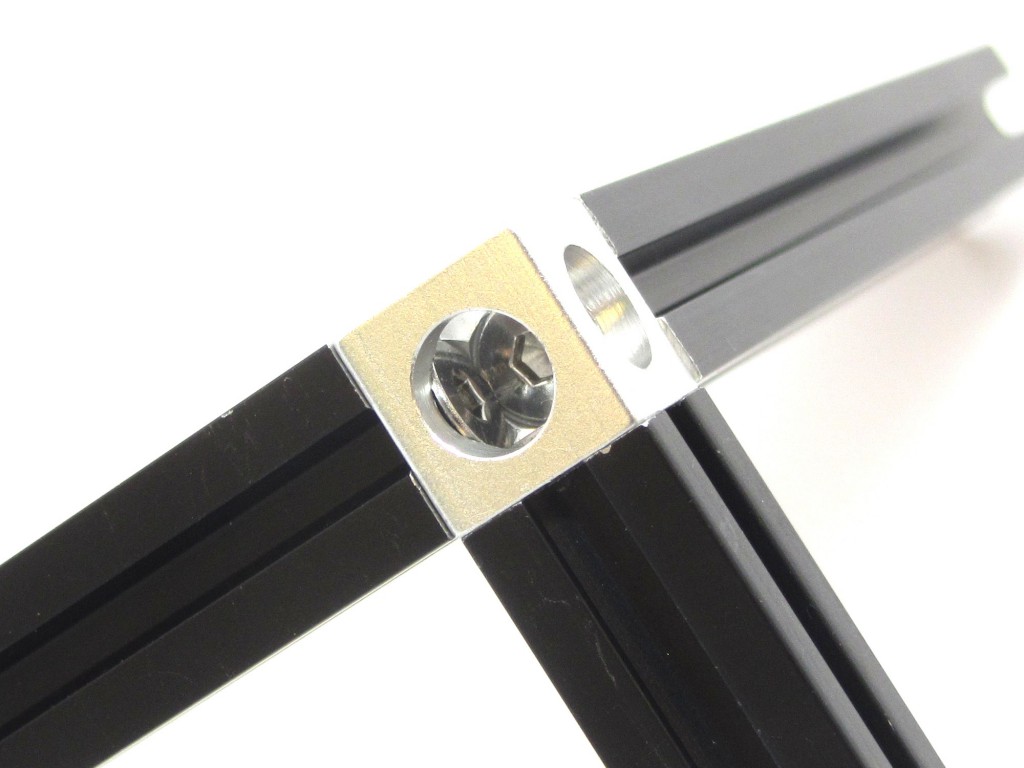

Later that evening we did some more testing and found that this batch of corner cubes is indeed different. The bolts do need sink in as deep. We are talking micrometers here. Here is a picture below.

We contacted the manufacturer. They are not to blame here. The difference is within their tolerance. There is a little room left. We made new drawings and are working on producing a new batch. Meanwhile we are thinking of reworking these corner cubes, 4000 pieces!

Johan did some testing on that as well. Here is picture with a reworked cube.

So for now it is back to the drawing board. Hope to have new, excellent, cubes here as soon as possible!!

p.s. The corner cubes were reworked and are back in stock.

We also worked on resolving the problem in the next batch. (20140613)

Author:

Marlies de Stigter

Team MakerBeam