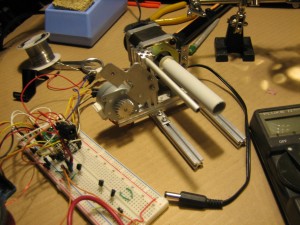

The MakerBeam knee joint video shown here is the first in a series of cSprings videos Sean Reynolds put online. A project page is to come but in the mean time you can find a couple of videos under his YouTube channel.

httpv://youtu.be/EPOEfrlR3uI

You should definitely see the other videos as well. They are great and very interesting. We of course love them because of the use of MakerBeam! I chose this video because at first glance it shows a simple setup.

It is a good example of MakerBeam as rapid prototyping tool. The added equipment, like the spring and hinges, make it clear you can add lots of things yourself. In the video an Arduino processor is driving the best servo on the market with a 5-20 lbs spring for flexability on the MakerBeam skeleton. MakerBeam provides the basics and you can build from there.

Team MakerBeam.eu