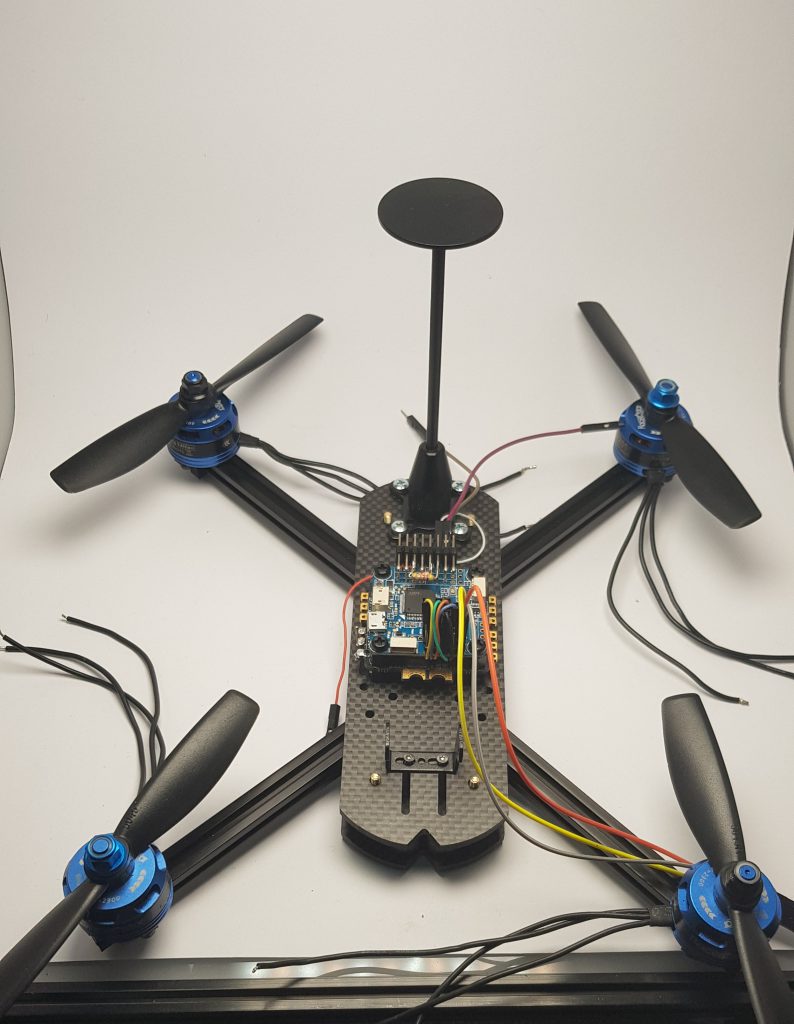

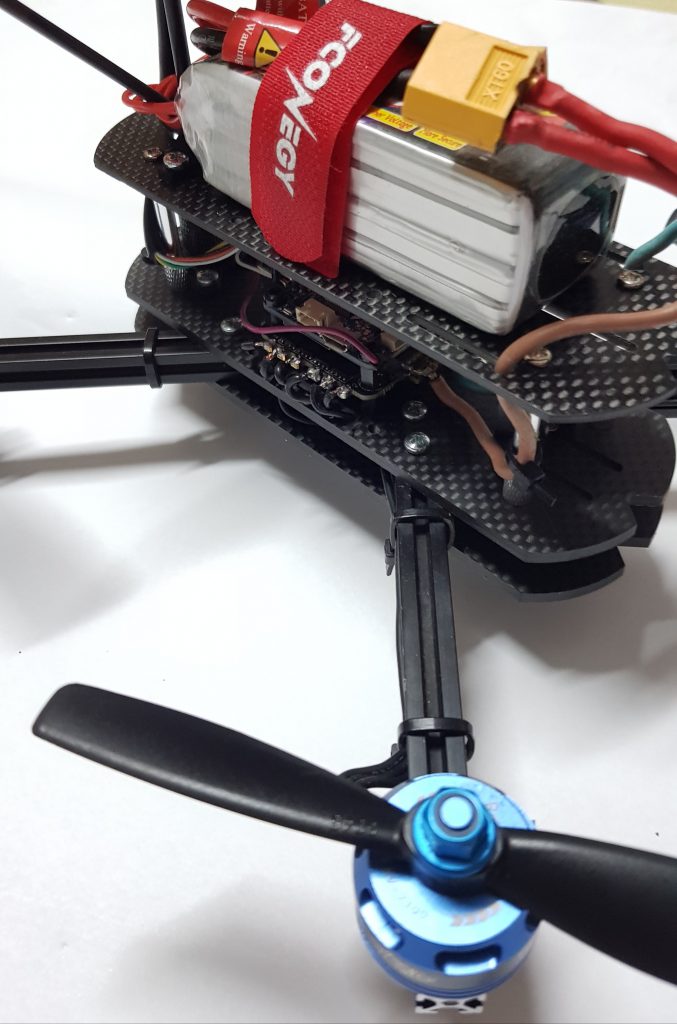

An FPV drone is a drone where the user has a first-person (FPV) view of the environment where the drone flies. Stefan from ConstrAct (Austria) made one and created a MakerBeam and Carbon based self-constructed FPV-Drone.

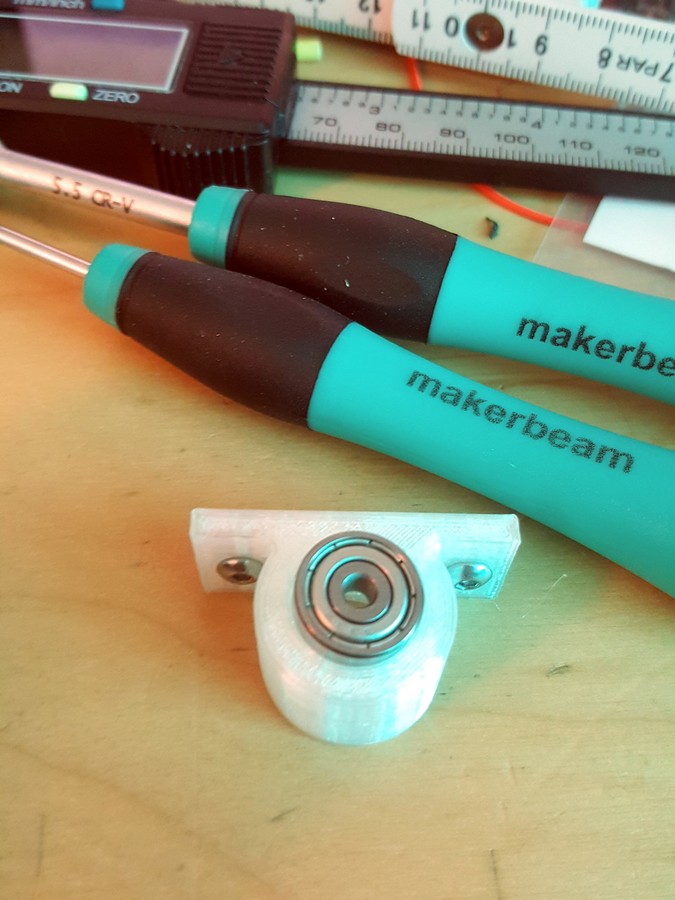

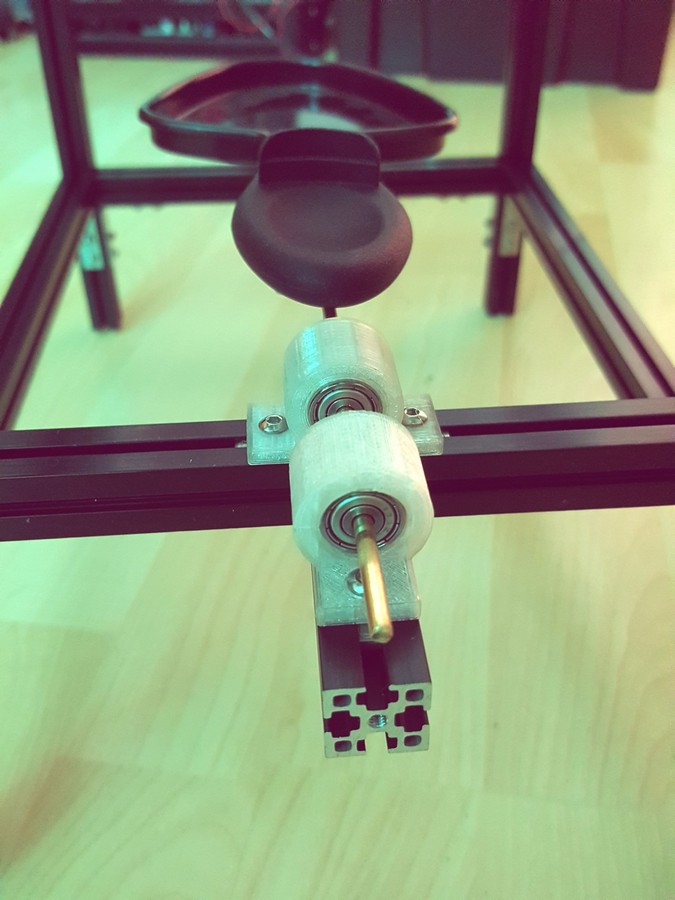

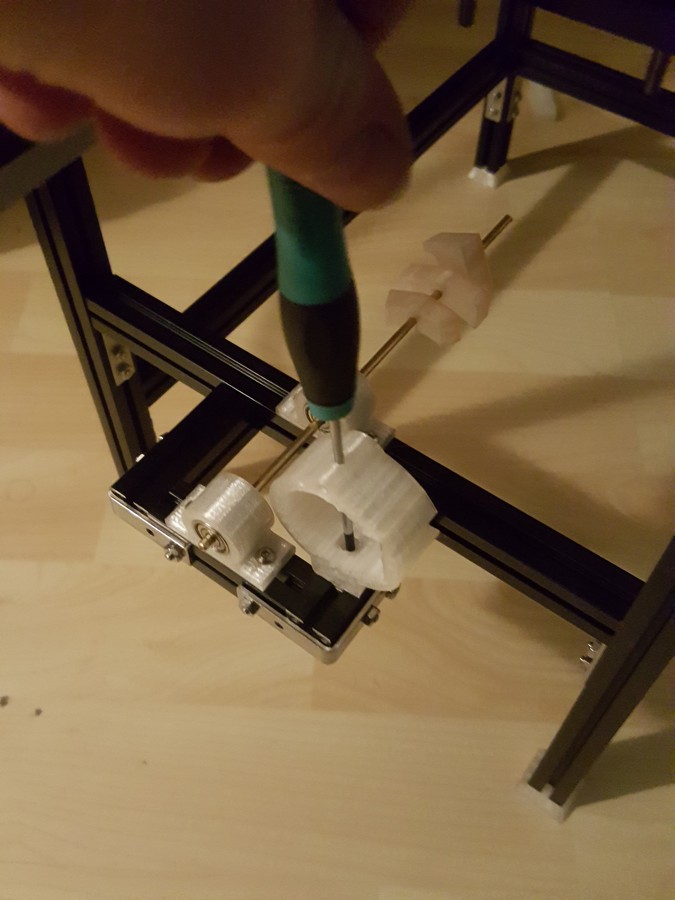

Stefan wanted to build a stable not to expensive drone to fly with a first person view. The chance to have this first person view from high up was the most exciting reason for him to start the build. He used MakerBeam for the arms and carbon for the frame.

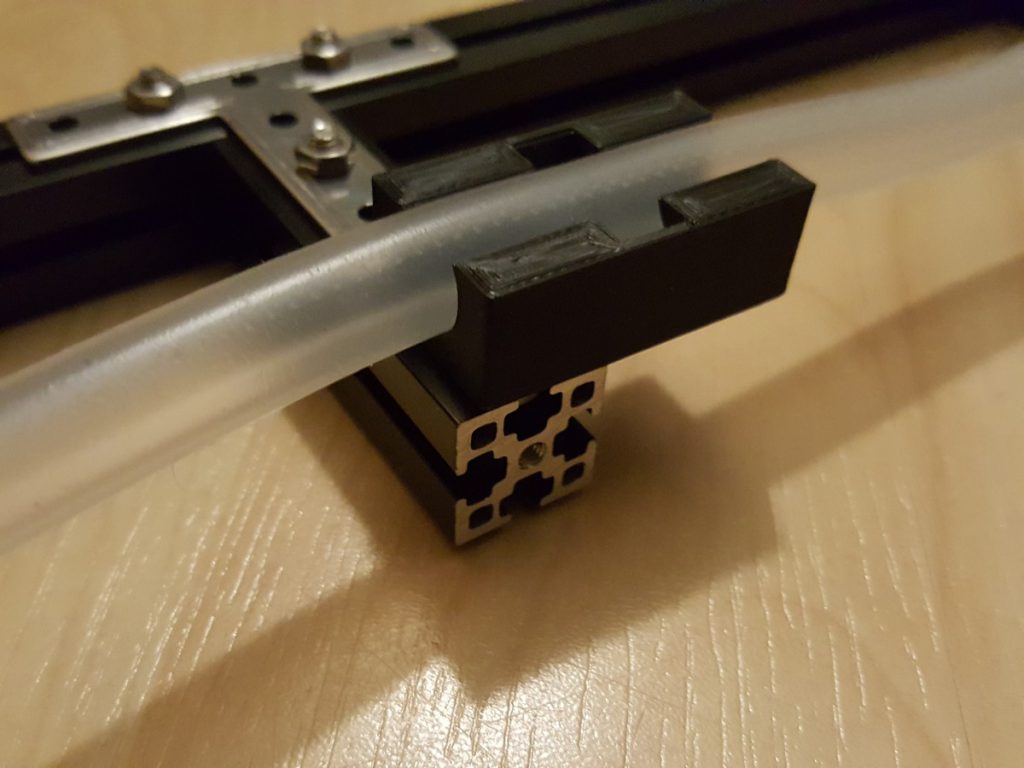

The MakerBeam arms are connected with T-slot nuts to the carbon frame – this is a very strong and reliable connection. It survived a couple of crashes, according to Stefan.

It was created for freestyle flying only. For racing it is too heavy. He already had to remove GPS and other parts.

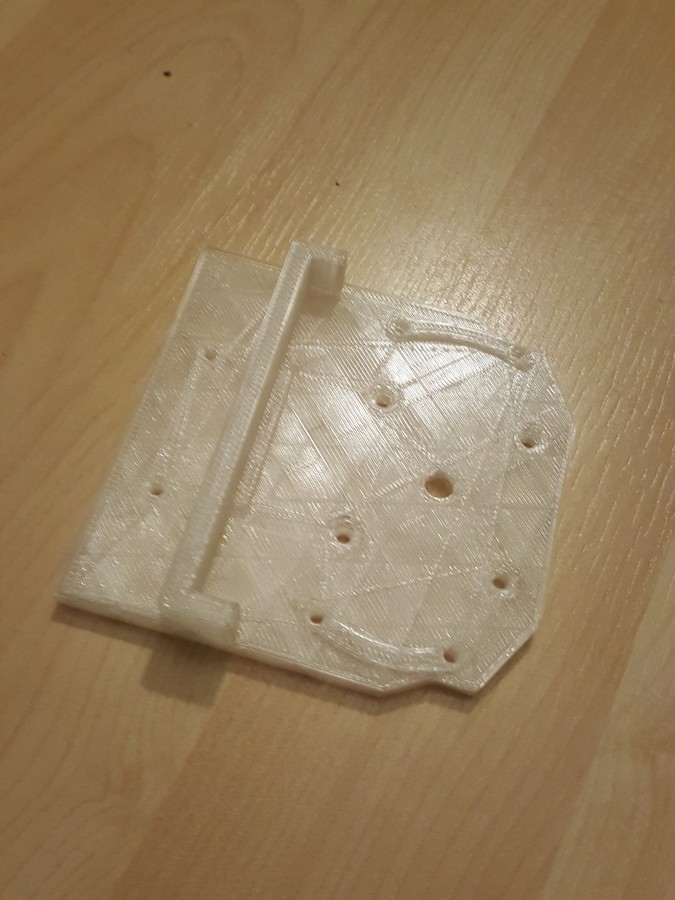

The carbon was cut on his CNC mill. The body was designed on fusion 360.

The electronic parts are:

– Omnibus F4 flight controller (holds the copter stable in the air)

– M8N GPS module (for return to home and Position hold)

– 4 in one ESC, (drivers for the motors)

– Runcam micro eagle camera and runcam sender (for first person view)

– Taranis receiver

– Inav Software

Team MakerBeam with Stefan Gschroefl from ConstrAct