In the previous post the Light Box was shown. The feet on the light box were different from the feet we sell. It turns out that Stefan made the feet himself.

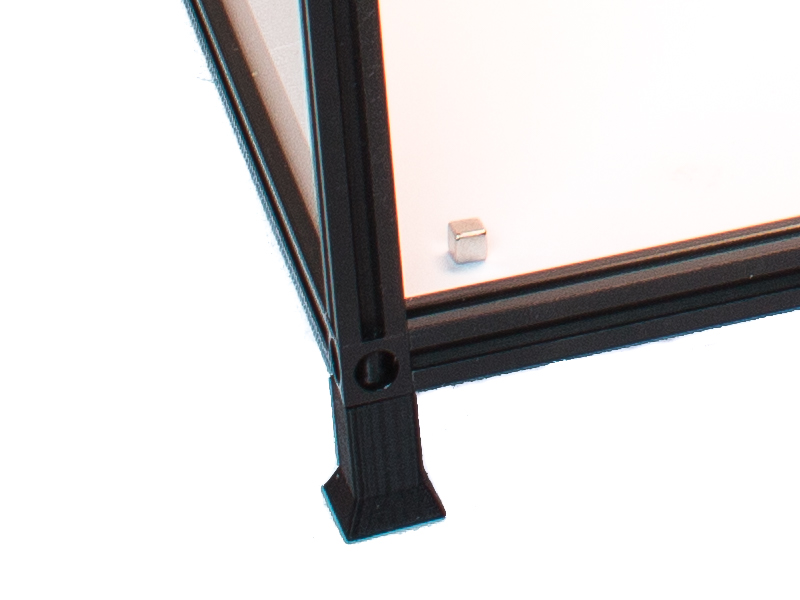

Stefan sent us the pictures of his Light Box (link to post webshop blog). The feet on the light box were different from the feet we sell. Stefan had actually designed and 3D printed new feet himself. The feet are a bit wider and higher. He needed more space from the bottom to fit the planned additional lighting. The extra is light is set to be mounted outside the box to shine into the cube from the bottom upward. See pictures of the special designed feet below.

He also made a photo cube which should rotate (driven by a small motor). Therefore he also created a special holder. See the first picture of the prototype below as well.

Stefan is planning to be present at the Maker Faire in Vienna. He wants to show all his work and all MakerBeam parts at this faire. The Maker Faire in Vienna (Austria) is scheduld for May 5 and 6. Here is a link to the Maker Faire Vienna website.