This blog post could as well be called ‘Buttons to suit MakerBeam 5’. We had problems with our screws and that is what the other blog posts were about. The other posts date from October 2011, December 2011, January 2012 and June 2012. Now we are testing a new bolt and there is another type of bolt in the making.

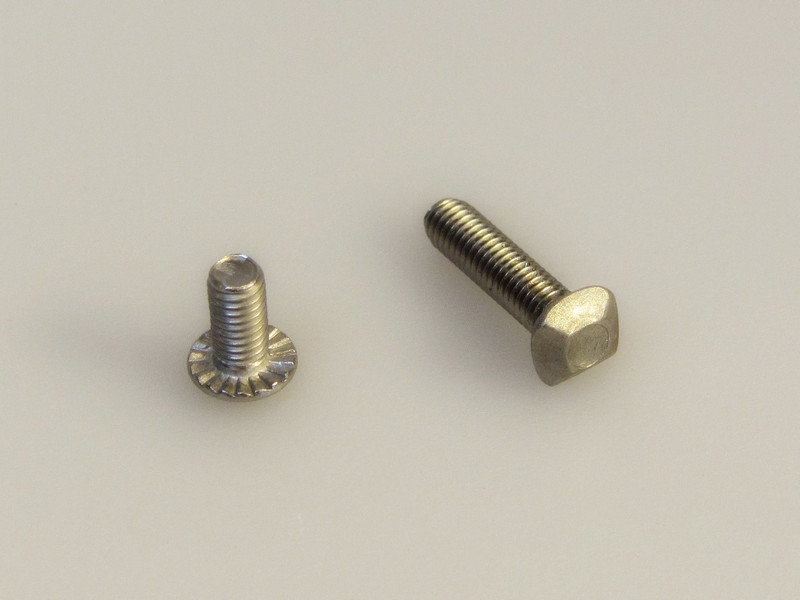

The pictures above give an overview of history of MakerBeam with bolts. From left to right there is the original bolt, our own improvement, the 12mm version, the new screw with serrated head bottom and a sample of a square-headed screw.

The picture to the left shows the original bolt 6mm length. We had hoped regular M3 screws would fit the Makerbeam profile. In the old version a regular bolt would rarely fit. This was in the back of our minds when we made our version 2.0 of the beams. Despite creating more room to accomodate the screws regular M3 screws still do not fit like we had hoped. The curvature is what hinders regular screws to fit. Otherwise the screws we sell are completely in line with the DIN standard 7380 (see ‘Buttons to suit MakerBeam 1).

We thought that some purposes, like using bearings, needed longer screws. Since we continously look to improve our product we consequently had them made in 12mm length. The picture above on the right shows the 6mm and the 12mm length.

Already then we were looking for other options to optimize grip. We thought of using washers. This idea was dismissed, too much of a hassle. Just when we thought we could not improve on the screw there was the suggestion of using bolts with a serrated head bottom, see picture above on the left. The serration gives the bolts a little more gripping quality. These serrated screws are available now. A bag with about a 100 pieces will be added to every starter kit to test them.

Another screw we are looking at is square-headed. Since using regular screws still is not much of an option we can set our goal differently: total grip all of the time. We received unpolished samples of square-headed screws that are chamfered a bit. Grip is absolutely secured using these screws. A sample is pictured above on the right. They have a downside though. They damage the surface a bit. Despite this downside we are thinking of these screws as the replacement of the screws we currently sell.

Occasionally we receive a message from a customer telling us that sometimes tightening a screw is not possible. Tightening is not a common problem, but still these square-headed screws will end any occurrence once and for all.

Do not think we are done once the square-head bolts are for sale. Still on our wish list is a screw with a rectangular screw head. Think of a screw head with wings. A rectangular screw head will will give the possibility to add screws midway. You can insert the screw midway of a beam and turn it 90 degrees to ensure tightening. This will make it easier to add screws to an almost finished structure.

Team MakerBeam.eu