We changed to a new webshop. The blog featured on our website will have all the latest news. This blog will be updated with customer projects and other news items.

For all the updates please visit our website and look under ‘Blog & News‘ or check our Facebook account. You can also find us on Twitter @makerbeam.

Looking forward to keep you updated and communicate with you through these channels.

Team MakerBeam

p.s. This blog was edited on August 12th, 2016. We expected we could no longer make use of it after we stopped using our old website. No updates were posted. Since it is still circulating we reconsidered and started updating again.

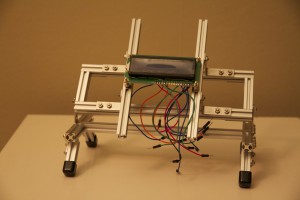

You can move video and photo-cameras on a slider to make attractive recordings. Moving time-lapse recordings with a DSLR or arbitrary video-camera movements are the main applications of the kit. The kit can also be used for completely different purposes where linear motion is needed (see end of the video below).

You can move video and photo-cameras on a slider to make attractive recordings. Moving time-lapse recordings with a DSLR or arbitrary video-camera movements are the main applications of the kit. The kit can also be used for completely different purposes where linear motion is needed (see end of the video below).