Introduction

Everyone of you who already used MakerBeam knows how difficult or rather time consuming it is to construct a corner out of three beams. Beside that, it costs a lot. You need up to three L-Shaped brackets, 12 bolts and 12 nuts. A new product solves this issue. It is a so called ‘Corner Cube’: a single piece of aluminum and three screws.

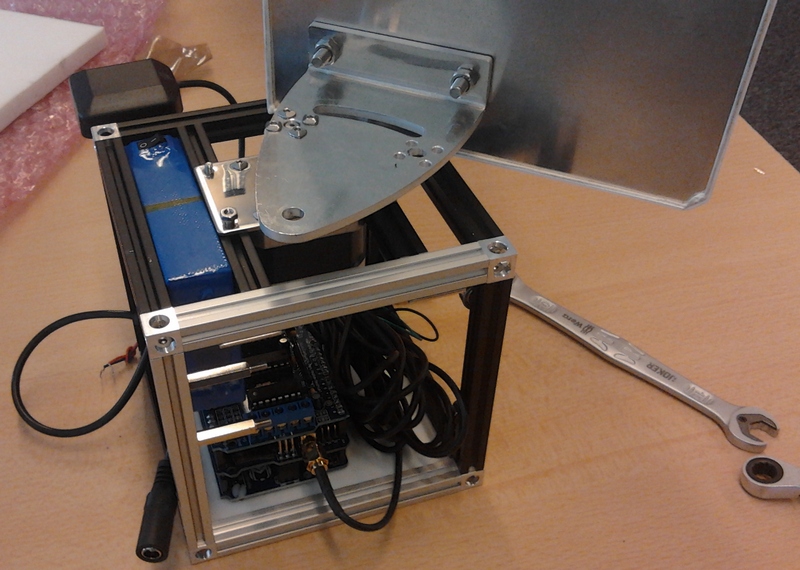

The biggest advantage of this new product might be that you can finally construct cubic corners. With the old method, using the L-Shaped brackets, you could not construct a cube as one beam was always “sinked” into the other. The new Corner Cubes connect the beams at their faces and therefore it becomes possible to create cubes as shown in this picture below.

Stability

Let’s start with the most obvious factor, stability. So far, we have all been used to the flat brackets which are screwed onto the beams with two screws per beam. The resulting joint provides a very stiff connection, see left picture below. It is obvious that the Corner Cubes will not provide the same joint strength due to their different design. However, our tests showed that this will not be of any issue for most applications. If required, the connections can be reinforced using the 90° corner brackets as shown below to the right.

Precision

This point is probably not that obvious at first, but after some thinking it becomes clear that the precision of the cubes themselves and especially the tolerances across different cubes matter a lot.

We have taken some measurements and the results were quite satisfying. From 12 cubes, we’ve found none that had difference from side to side larger than 0.1mm. A comparison between the dimensions of the 12 cubes lead to the same result: they are all equal to each another within a tolerance of 0.1mm.

Compatibility

The Corner Cubes only work on the new MakerBeams which have a threaded hole at each end. Therefore they can not be used with your current set of MakerBeams unless you have the tools to make a hole and wire tap the ends yourself.

This is also a limiting fact when it comes to custom sized beams. As the threaded center hole at the end of each side is not continuous, you also have to bore a new center hole and cut a thread yourself. However, only few people might have the tools and the knowledge to do this. Good thing that you can still use the old method!

Costs

Finally, let’s take a more detailed look at the costs. As mentioned earlier, you need quite a lot more pieces to build the traditional corner.

| COST COMPARISON CORNER BUILD | |||||||

| Corner Cubes | 90º L-brackets | ||||||

| Piece | Price | Quantity | Total | Piece | Price | Quantity | Total |

| Cube | €1,06 | 1 | €1,06 | L-Bracket | €0,65 | 3 | €1,95 |

| Bolts | Included | – | Bolt | €0,06 | 12 | €0,72 | |

| Nuts | Not needed | – | Nut | €0,03 | 12 | €0,36 | |

| TOTAL | €1,06 | TOTAL | €3,03 | ||||

A traditional corner costs you €3,03. Compared to the €1,06 you have to pay for a ‘Corner Cube’ corner, that is quite a lot! Note: You can use just two 90° brackets to create a corner but then not each beam will be connected to both others.

Conclusion

The Corner Cubes do not only make it possible to create cubic corners, they are also about three times cheaper. Should you already own the new MakerBeam with the threaded hole at the ends, the Corner Cubes only drawback are the lower stability compared to the traditional method. However, it is possible to use the 90° corner brackets to reinforce the construction.

Author: Joel Bodenmann of B-Electronics