Hendrik-Jan is a student who just started his bachelor studies in electronics September 2019. He made us a pancake machine.

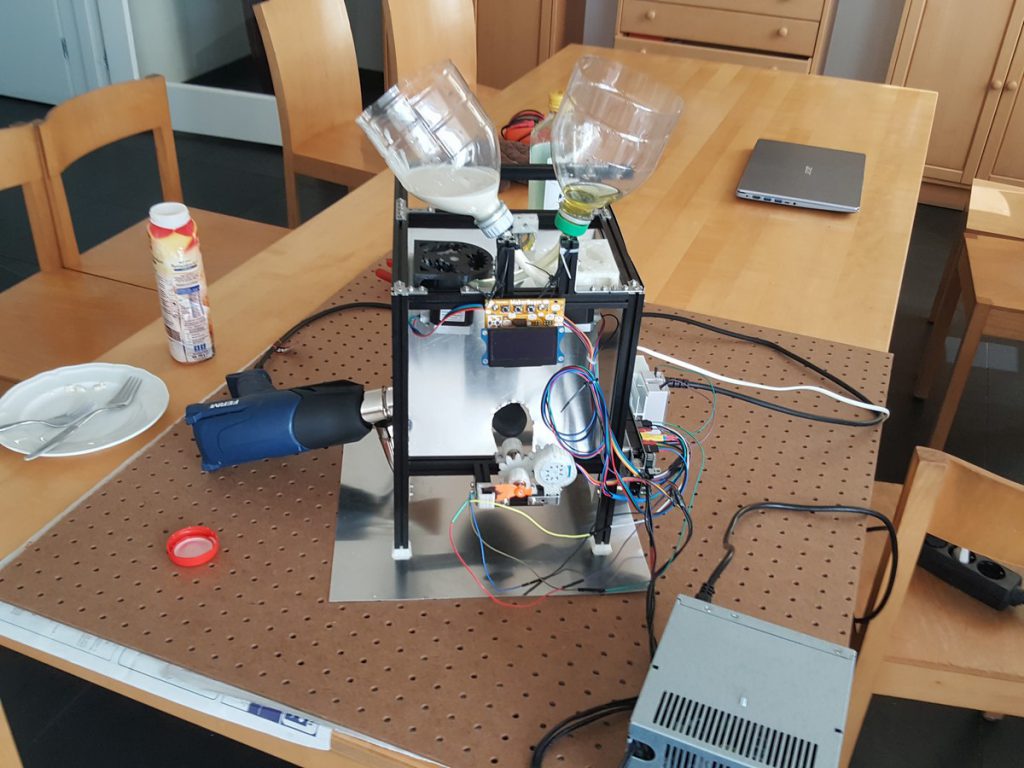

Heating the pan was a bit difficult. Hendrik-Jan considered using a the heating module of a blowdryer. But this proved to be to challenging and time was running out. Before the start of his bachelor studies the pancake machine needed to be finished. He chose to use a heat gun.

The tilting of the pan worked well, but the sliding off never really happened. The pancakes never got baked really well. The pancake would almost burn into the pan. So that it would not fall out of the pan when you turned round. No matter how much oil was in the pan. This probably happened because the temperature of the pan became too high. The oil burned away a bit and with it the batter that touched the pan. Adding a temperature sensor to the pan that could act as a thermostat could fix this problem. Hendrik-Jan considered such a system, but chose not use one. It would have been both challenging to mount a temperature sensor to the pan and would have made the code a lot more complex. What he instead hoped for was that he could regulate the temperature of the pan a bit by aiming the gun on the right spot on the right distance from the machine.

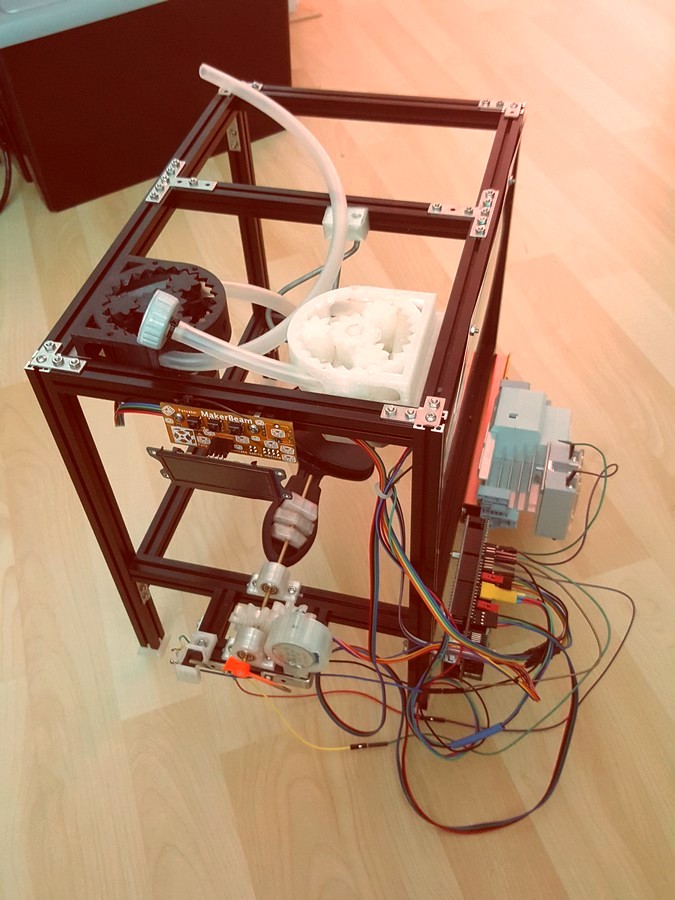

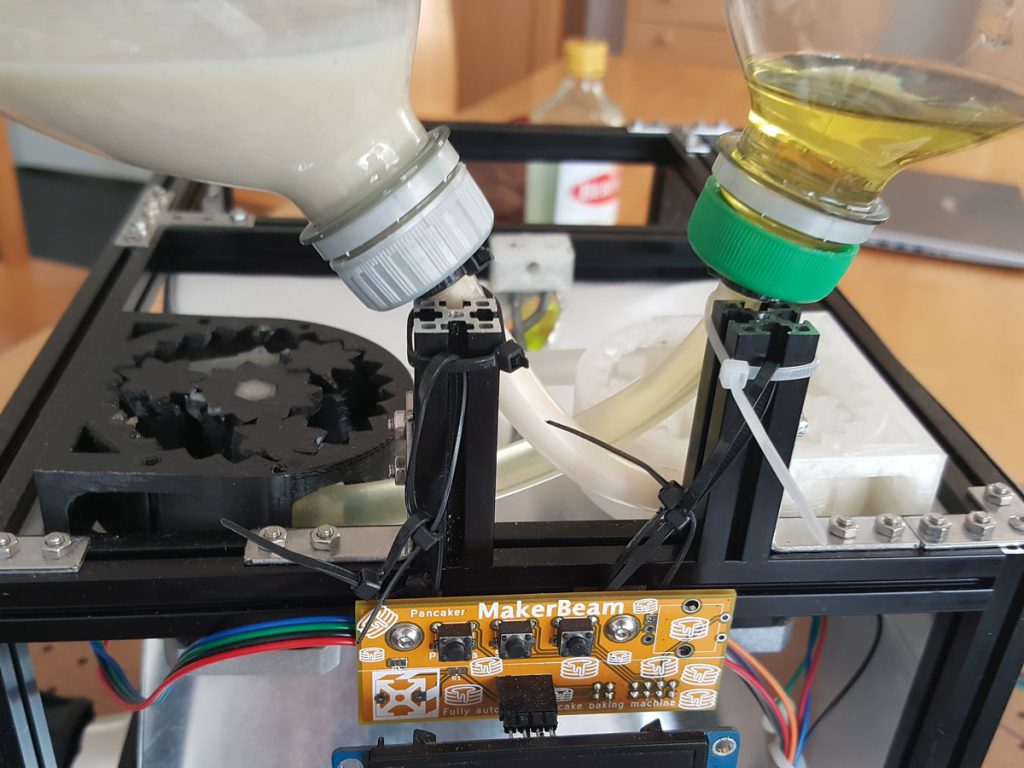

The pumps worked well. They only have have one problem. There is still a tube of approximately 20 centimetres until the tube ends above the pan after the fluid is pumped from the reservoir through the pump. Oil and batter slowly drip into the pan instead of falling all at once. There should be a vacuum in the tube to prevent this. The tube that was used is pretty wide, so this vacuum to hold the fluid in place was not there. This meant that after pumping, the fluids would still leak out of the tube for a pretty long time. In retrospect Hendrik-Jan thinks that the best way to solve this is to let the pump retract, just like 3d-printers do with their filament. This means that after pumping the fluids to the pan, it would pump back a little bit so that the tube after pumping is empty.

As a reservoir for both the butter and the oil, Hendrik-Jan used a PET-bottle neck. He could easily hot-glue the tube into a bottle cap. The reservoir on the right (figure 5) leaked a bit though, eventually leaving a mess everywhere. In hindsight a funnel maybe would have worked better.

Even though the machine did not really work as a fully automatic pancake machine Hendrik-Jan is still pleased with how the machine turned out. He learned a lot in the process of making and testing the machine. The use of MakerBeam profiles made it possible to divide the making of the machine into separate projects without having to worry about the whole. All the created elements could always be fastened to the MakerBeam framework anyway. This meant he could focus on one project at a time without having to worry how the created element in that project would fit the whole.

Team MakerBeam