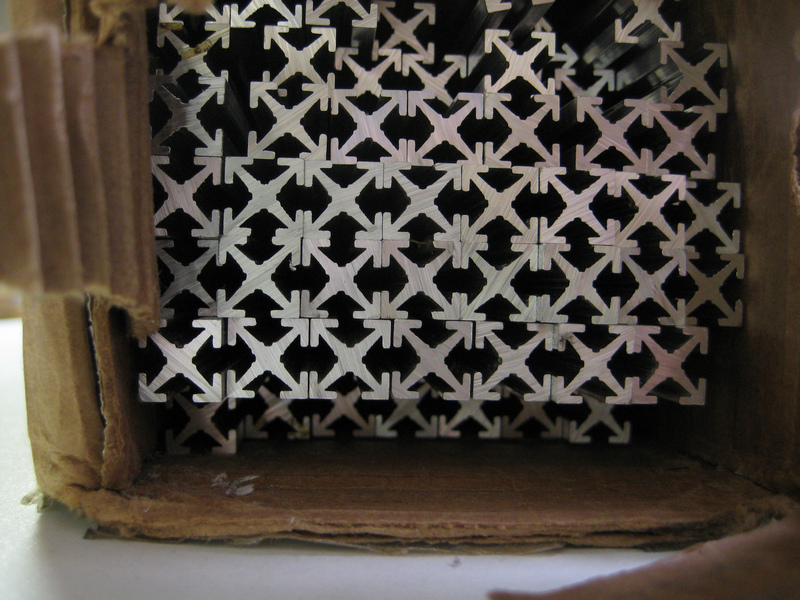

Everything makerish and beamish – and this new post is definitely beamish. On Kickstarter there is a new and exciting new project to back. OpenBeam – An open source miniature construction system.

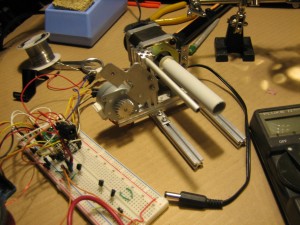

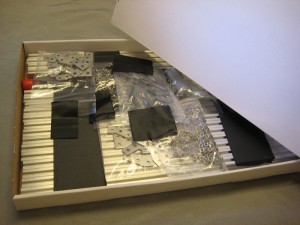

OpenBeam looks like a great addition to what is already on the market: Microrax and of course MakerBeam.

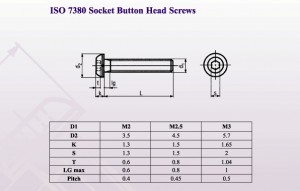

We love it because is addresses the problem we came across. Since the MakerBeam profile uses the M3 standard we had hoped M3 bolts available in any hardware store would do. As mentioned in our blog posts (1, 2 and 3) we could not find a steady supply of M3 bolts. We got lucky on a few occasions, but finally we had to resort to making our own 12mm MakerBeam bolts. Nice as this sounds it is not what we aspire. It is great that OpenBeam tries to resolve this.

It is also the reason why we are currently working on MakerBeam version 2.0. The first samples are in and look promising. The freedom open source gives people is great. We would love to bring OpenBeam overseas as well when time comes. There are a lot of things still waiting to be made!

Team MakerBeam.eu