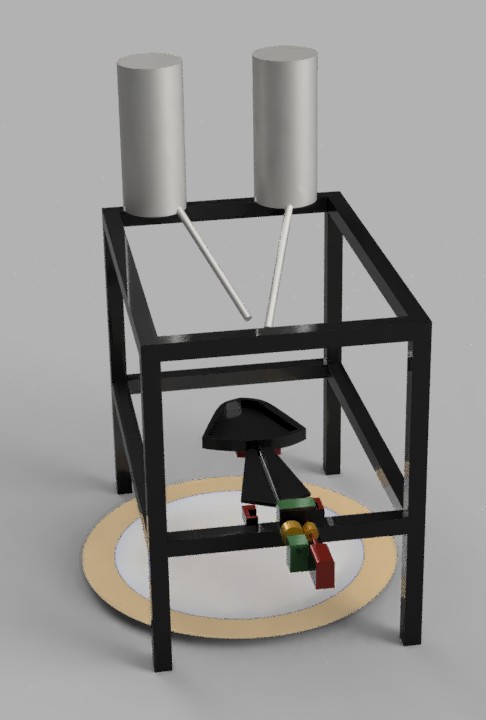

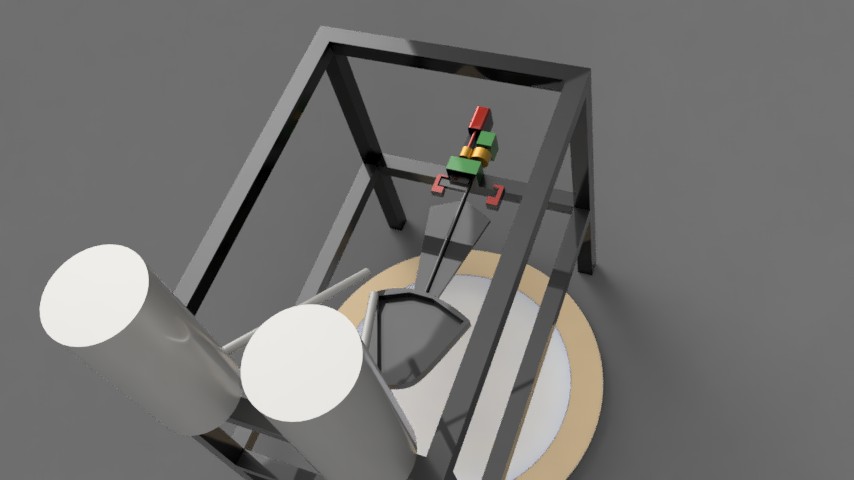

Hendrik-Jan is a student who just started his bachelor studies in electronics September 2019. Hendrik-Jan made us a pancake machine.

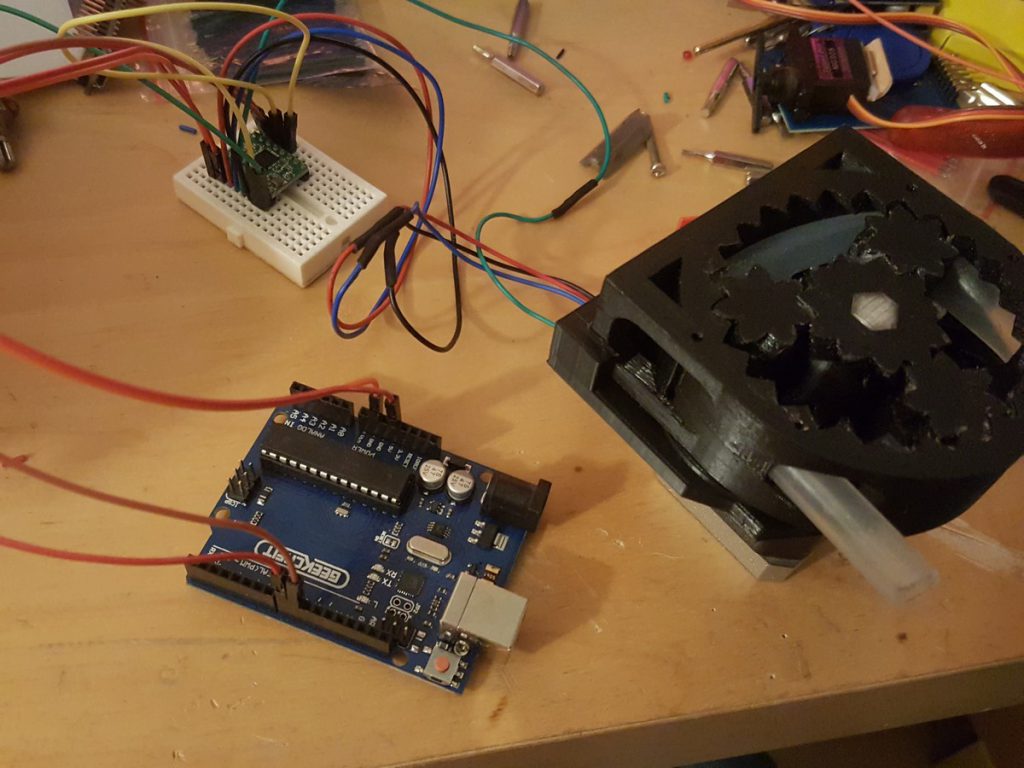

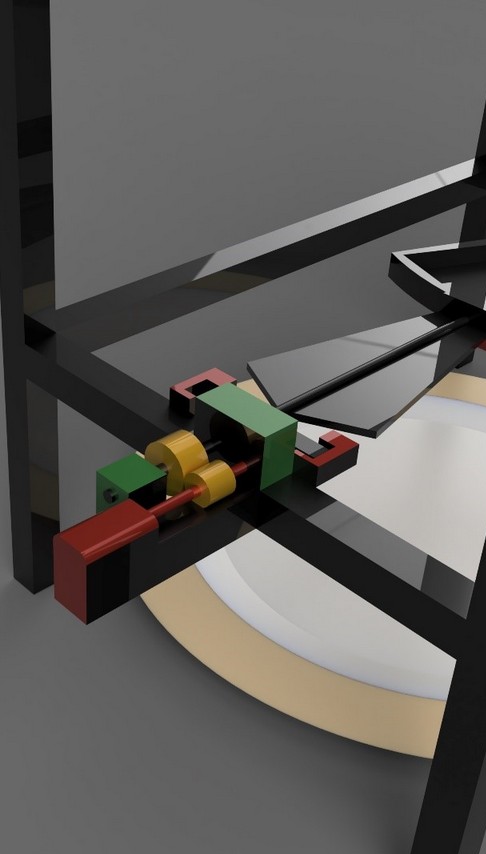

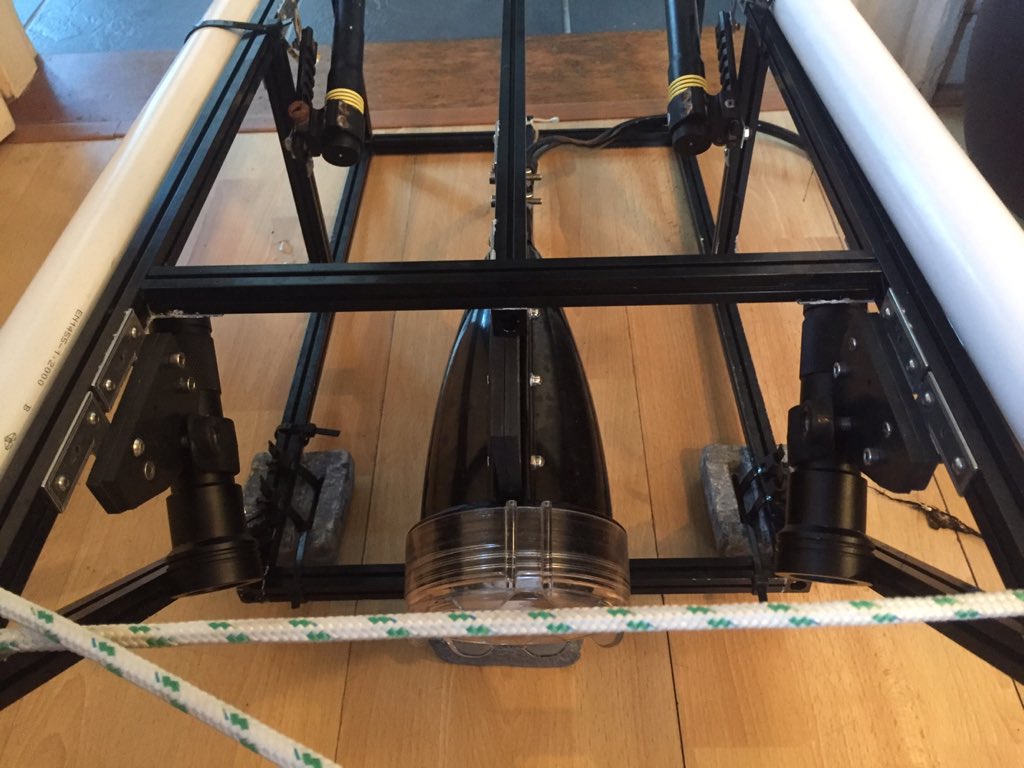

He first concentrated on creating the pumps to get the necessary oil and batter down to the pan. He created two 3D printed peristaltic pumps. Bigger sized versions from what Drmn4ea posted on Thingiverse. (Link: https://www.thingiverse.com/thing:454702 ). The gears and the body were altered, not just in size, but also to fit the tube in the pump. You can see his design here: https://www.thingiverse.com/thing:3885332. With a lot of grease added these pumps worked very well. See below for videos and pictures.

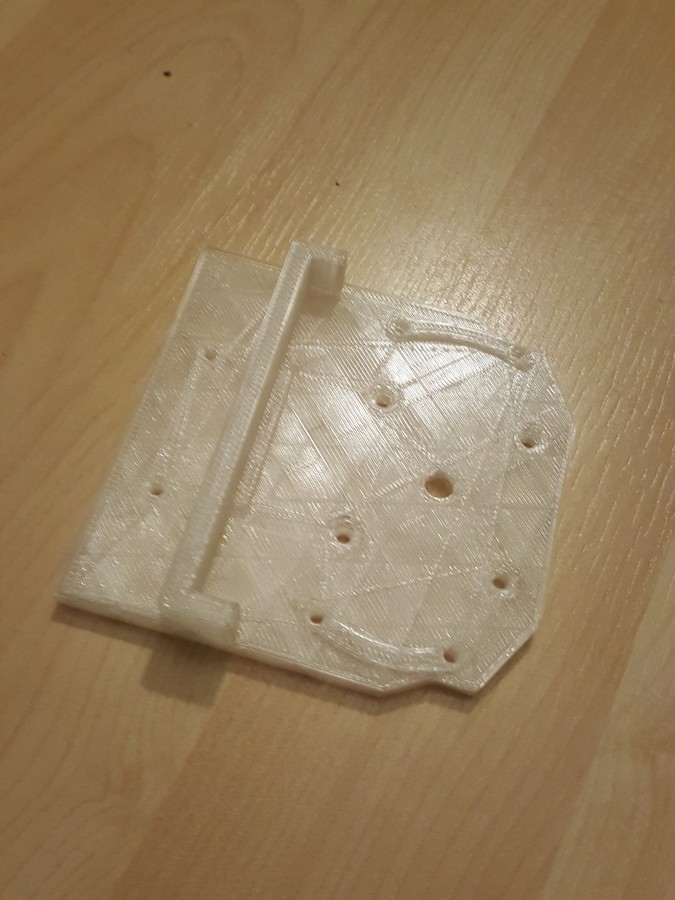

In order to fasten the pumps to the framework he created plates that could serve as brackets.

The use of MakerBeam profiles helped to divide all the different parts of the machine in separate projects. This meant Hendrik-Jan could focus on only one item, without really having to worry about the rest of the machine. All the different elements created in the differrent projects could be fastened on the frame anyway.

Here is a video of a test run of a pump.

Team MakerBeam