Category: Projects MakerBeam

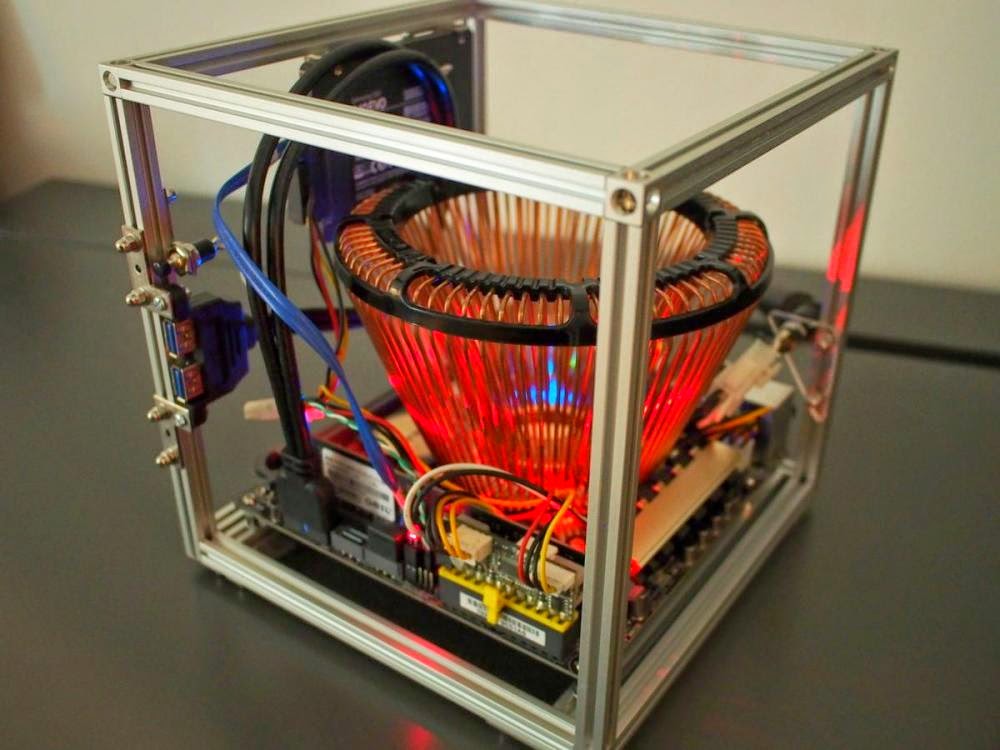

Lalita foldable 3Dprinter

Selfmade custom lengths

Max made this project with selfmade custom lengths. The beams were 200mm and then cut to 185mm.

Max made this project with selfmade custom lengths. The beams were 200mm and then cut to 185mm.

Max his tools: clamps and a hack saw.

“Hi,

So I ordered another lot from chartup.com and when this lot arrived they were the new version where the centre holes goes all the way through. Excellent! I cut them to length using clamps and a hacksaw in my kitchen. Then tapped the threads using an M3 tap, a power drill and some bicycle chain oil. It all worked perfectly so it is possible without proper tools 🙂

Thanks,

Max”

If you want to know more about Max his project please visit the fanlesstech website: http://www.fanlesstech.com/2015/01/nofan-cr-80eh-build.html

Thank you Max!

Team MakerBeam.eu

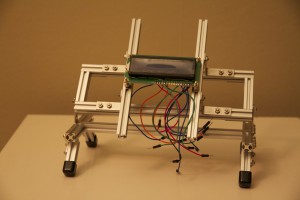

PCB and component holder project

We would like to share with you a work-in-progress, but still an inspiring project: creating a PCB and component holder, which is designed to make soldering easier.

The project is running in the hands of Mark Swinhoe, and he shared with us a little background about it.

“This little tool was inspired by how expensive professional PCB holders are, and how they immediately reminded me of MakerBeam. The holder allows you to angle the component, and use the mounting holes to keep it in place.

The vertical beams can be easily loosened for different width of components and the PCB standoffs slide up-and-down the vertical beams for height adjustments. If you need more space from the vertical bars, then you can add another set of standoffs on top of the existing ones, or just attach longer standoffs. The components are held really well with MakerBeam, and it has a very solid base.” – (by Mark Swinhoe)

Mark, thanks for sharing it with us. We wish you more fun with it and a successful result. We hope, that we can see your robot running-around soon.

Team MakerBeam

Prototyping a Dynamic Wifi Antenna Rig

Wandy is designing an antenna rig with the capability to track its wifi AP via GPS and motion sensing. This rig is designed to be installed on maritime vessels in order to provide a high quality wifi link to shore based access points. The built-in GPS receiver will give the rig its current position and heading and calculates its angle towards the shore based AP.

Wandy is designing an antenna rig with the capability to track its wifi AP via GPS and motion sensing. This rig is designed to be installed on maritime vessels in order to provide a high quality wifi link to shore based access points. The built-in GPS receiver will give the rig its current position and heading and calculates its angle towards the shore based AP.

The shore based AP locations are hard-coded into the rigs software, and compared with the rigs current sector in order to allow several different AP’s to be registered according to location. This current model has not got the gimbal system installed yet. This will counter wave movement of the ship by motion sensing and keep the antenna levelled with the AP.

This prototype was built using Makerbeam. Makerbeam gave us the flexibility to quickly change the design in order to develop new features. The first housing, was 10 x 10 cm and turned out to be too small to fit the embedded router-board. Changing the dimensions was as simple as changing your socks, and in no time we had a larger base.

One of the things that makes Makerbeam so well suited for this project is its aesthetic properties.The black anodised beams have a beautiful finished look to them. With a couple of black polystyrene sheets and a Stanley knife, the prototype looks the part in a matter of minutes.

The threaded beams enabled us to use the corner cubes and this gives the prototype a real design look. Makerbeam enabled us to make a prototype we can actually show to potential customers without having to make too many excuses.

In the video you will see the device waiting for a GPS lock and doing a calibration by the flick of a switch. Note the awesome design lights on the bottom of the rig.

Ammer van Bussel

Netwerk engineer

Wandy

The Boss

Mr Peters from the International School of Prague made a great robot called The Boss. It is a great little robot with MakerBeam, arduino and 3d printed parts combined. Here is a little video to introduce the little guy.

httpv://www.youtube.com/watch?v=c4eTYrZqZ1w

Team MakerBeam.eu

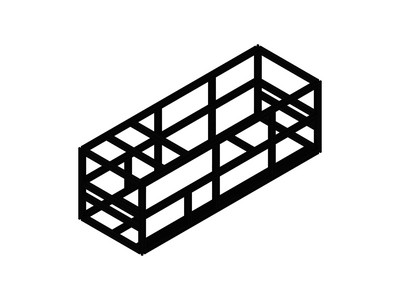

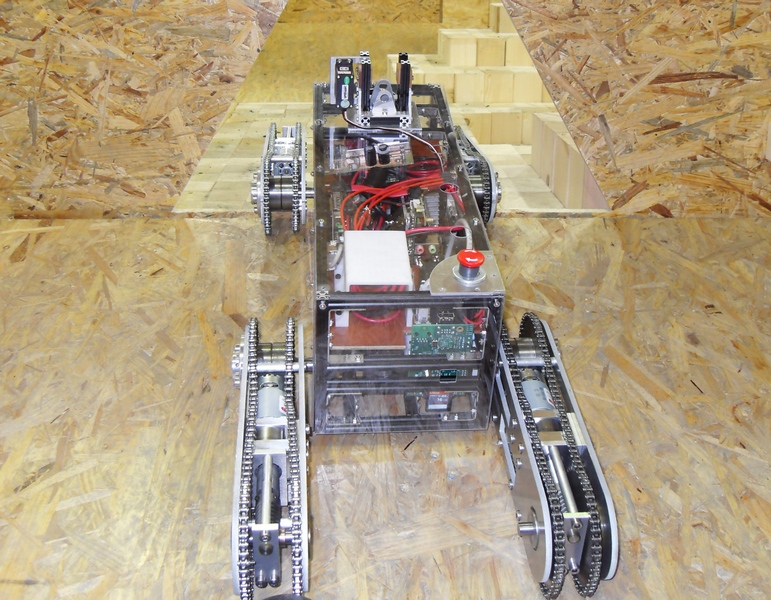

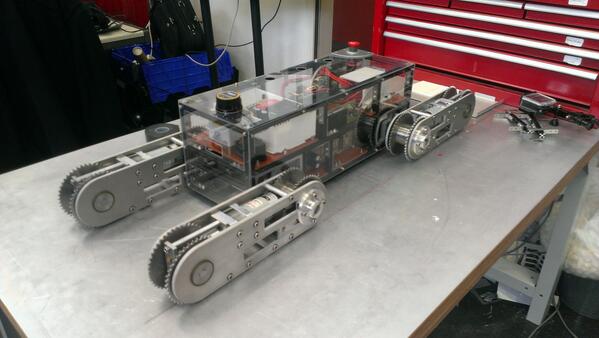

Warwick Mobile Robotics and the RoboCup Rescue competition

Warwick Mobile Robotics is a research project carried out by a team of fourth year undergraduate students at the University of Warwick in the UK. The project involves the creation of a search and rescue robot designed to locate survivors in hazardous environments, such as earthquake disaster zones; removing emergency service personnel from danger.

The project has been running for the last seven years. Each team has made alterations to develop the previous robot design. This year, we are designing, manufacturing and programming a whole new, smaller, lighter robot capable of navigating moderate terrain in a smaller environment.

The project has been running for the last seven years. Each team has made alterations to develop the previous robot design. This year, we are designing, manufacturing and programming a whole new, smaller, lighter robot capable of navigating moderate terrain in a smaller environment.

The aim is to develop a modular structure which will allow the robotic platform to be easily modified by future teams. The design will be focused towards achieving a low cost model with key features such as reliability, maintainability and modularity. It must have a maximum turning radius of 0.5 metres and a maximum weight of 25kg which makes it deployable by one person. The long term aim of the project is for the prototype to be further developed by future teams into a commercially viable design.

In order to achieve these design aims we have opted to use MakerBeam and OpenBeam for the chassis and arm structures. The off-shelf beams and fittings provide the perfect solution to our design requirements. The beams themselves have the required structural integrity, are lightweight and can easily be cut to length. Assembly times will be short due to the design of the beams and future years will be able to modify the size of the structure with ease. This suits the modularity of the design.

In order to achieve these design aims we have opted to use MakerBeam and OpenBeam for the chassis and arm structures. The off-shelf beams and fittings provide the perfect solution to our design requirements. The beams themselves have the required structural integrity, are lightweight and can easily be cut to length. Assembly times will be short due to the design of the beams and future years will be able to modify the size of the structure with ease. This suits the modularity of the design.

The team are testing the robot’s capabilities at the RoboCup Rescue competition held in Germany in Magdeburg during the Easter break (April 3-5). The RoboCup Rescue is a competition that tests the robots search and rescue abilities in a simulated disaster environment. The team has decided to enter this competition as it provides an exciting engineering challenge beyond the scope of our undergraduate project requirements and a socially significant real world application for mobile robotics. The team won “Best in Mobility” from 2009-2012, “Best in Manoeuvrability” in 2012 and won the competition in 2010. Last year, the team entered the World RoboCup competition for the first time and placed 10th in the world. Our aim for this year is to enter two robots into the European competition for the first time.

The team is really grateful for the support of MakerBeam in the creation of our robot and we are excited to assemble all of the parts which are currently being manufactured!

24/02/2014

Lauren Rutter (Sponsorship and Publicity Coordinator and Chassis Designer)