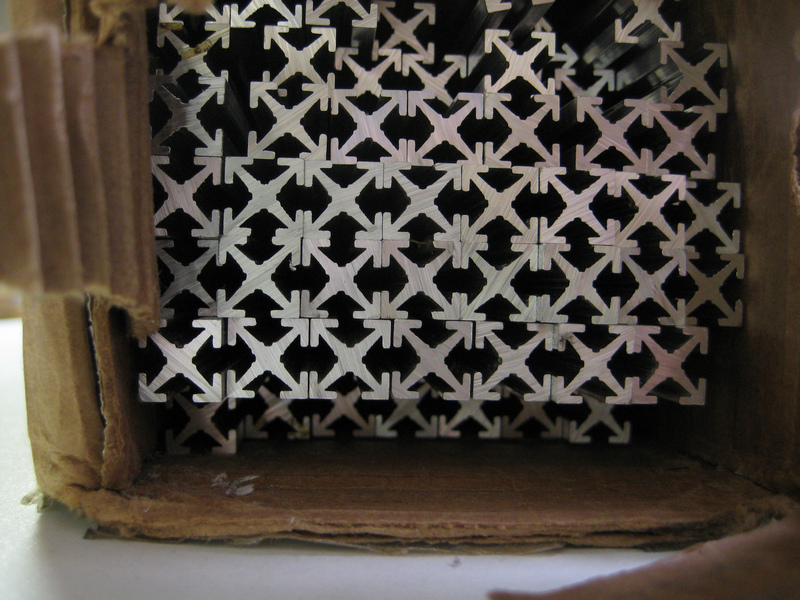

Sam Putnam was the one who came up with the idea of MakerBeam. You can find his story on Kickstarter. He thought of all the measurements, bracket types, quantities etc. and had the first batch made. Johan here thought it was a very good product. He backed Sam his Kickstarter campaign. Unfortunately Sam did not take his idea further. The next step, a website: makerbeam.com, remained ‘under construction’ for about three years. In 2011 we created the webshop makerbeam.eu and made makerbeam available here in Europe. We are happy to announce that MakerBeam.com is officially in our hands. It is no longer under construction and redirects to makerbeam.eu.

Johan here thought it was a very good product. He backed Sam his Kickstarter campaign. Unfortunately Sam did not take his idea further. The next step, a website: makerbeam.com, remained ‘under construction’ for about three years. In 2011 we created the webshop makerbeam.eu and made makerbeam available here in Europe. We are happy to announce that MakerBeam.com is officially in our hands. It is no longer under construction and redirects to makerbeam.eu.

We innovated the beams and we are planning to innovate the website as well. MakerBeam.eu will pretty much stay as it is. We will renew our webshop on the Makerbeam.com address. So… we will try to avoid it but maybe you will stumble on an ‘under construction’ notice on the .com website again this year. Sorry!!!

Team MakerBeam.eu