It is a great time to be a maker! Equipment to make all sorts of machinery is more and more available for a good price. Sparkfun, Arduino and Adafruit have made a name in accessible electronics. More and more modular systems to construct a suitable framework for your own invention are coming on the market as well. Open source hardware is booming.

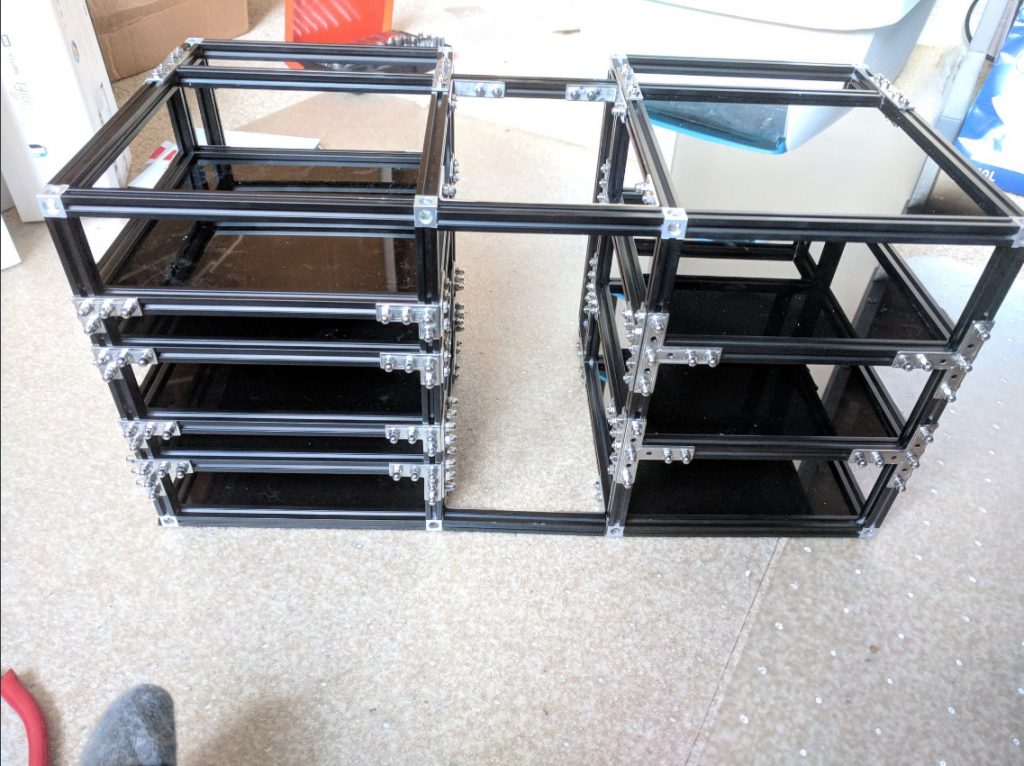

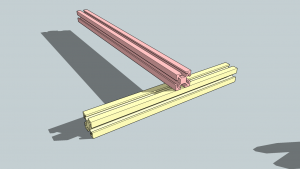

There are the systems based on a repetitive hole pattern (Bitbeam, Contraptor) and the t-slot style systems (OpenBeam and our own MakerBeam). Makeblock combines both styles. Leaving repetitive hole pattern systems aside, what is the difference between these open source t-slot style systems?

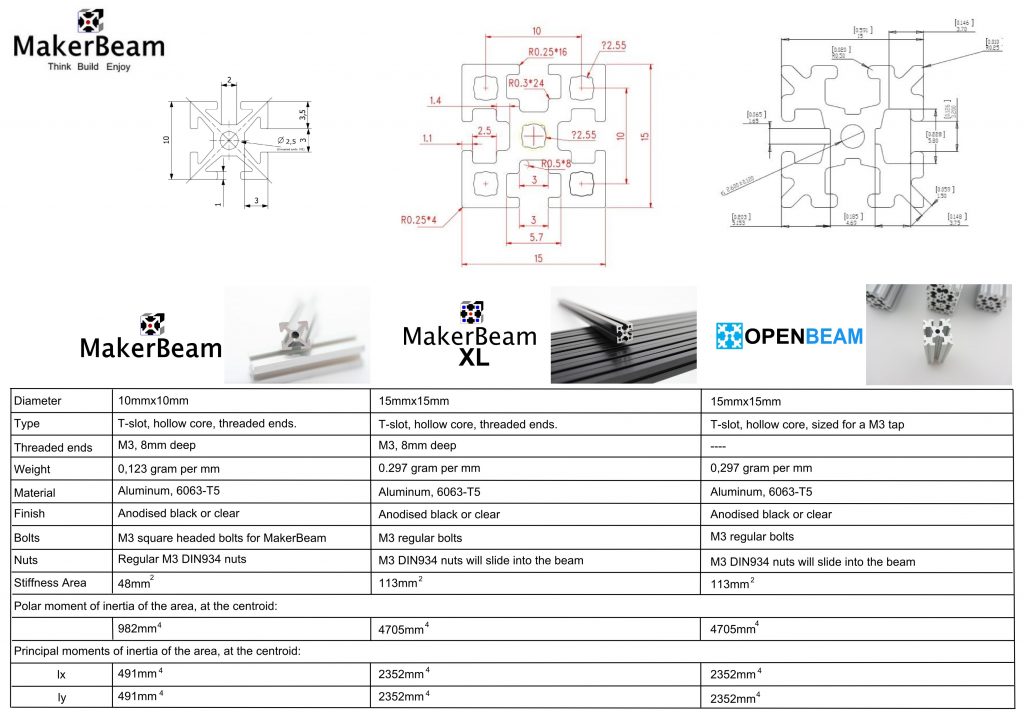

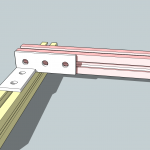

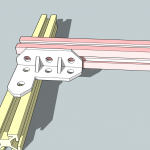

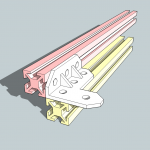

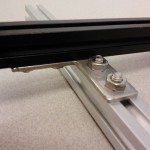

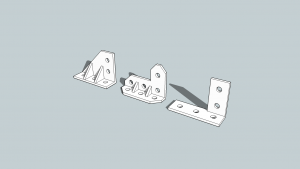

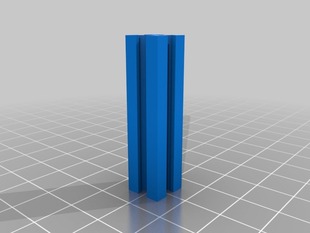

MakerBeam sells beams that are 10mmx10mm and available in different precut lengths. Longest beam available is 900mm. There is a precut kit available (lengths from 40mm to 300mm). The beams are an extruded aluminum construction profile. The profile is a simple mini T-slot. The beams are black or clear anodized. The plates and brackets are stamped metal. The beams and brackets can be connected with makerbeam bolts. Size used is M3. We do not sell electronics. On our website you can find specifications and a link to Thingiverse. On Thingiverse you can find design files for makerbeams and additional 3D objects.

OpenBeam created beams that are 15mmx15mm and normally available in a length of 1000mm. There is a precut kit available (lengths 30-300mm). The beams are an extruded aluminum construction profile. The profile is an intricate mini T-slot. The plates are injection molded out of a high performance fiberglass reinforced plastic to make it affordable. The beams and plates can be connected with standard M3 nuts and bolts. They do not sell electronics. You can download design files.

Makeblock is an aluminum extrusion based construct platform. The beams and brackets have repetitve hole patterns and a threaded slide combining the two systems widely used. The beams are available in 8mmx8mm and 8mmx24mm in two different colours, blue and gold. They sell several matching brackets, plates and pulleys. There are different kits available, including one that is lego compatible and a kit designed to be used for education. They do sell electronics. According to their website they will be open about their product and release information on their website.

MakerBeam is only just spreading to webshops all over the globe. In 2009 there was a Kickstarter campaign for MakerBeam. This is how we got to know the product. Makerbeam started early but never fully profited from its momentum generated by Kickstarter. Only after MakerBeam.eu was introduced here in Europe it slowly got some attention. We love the size of the makerbeams. 10mmx10mm looks great, almost elegant.

We are working on our product range. There is a servo bracket in the making and a different solution for connecting bearings will be introduced in our shop soon. Brackets, other type of bearings, gears and gear racks are under consideration. The focus here is on ready available products. Manuals are something we would love to add to our product, but are still struggling to make. Kits are something we are looking into as well. Electronics are not on the menu for us though. We want to provide a professional easy prototyping framework that can be used by makers at home or in the workplace. We think MakerBeam is highly suitable for industrial use. The place where the T-slot originates.

OpenBeam started with a kickstarter campaign this year. We already welcomed OpenBeam in April 2012 (see blog post then). OpenBeam is great because it addresses the problem we came across. Since the MakerBeam profile uses the M3 standard we had hoped M3 bolts available in any hardware store would do. We got lucky on a few occasions, but finally we had to resort to making our own 12mm MakerBeam bolts. Nice as this sounds it is not what we aspire. Remember that we are not the creators of MakerBeam. We are selling makerbeam and try to make it available on the market. It is great that OpenBeam tries to resolve this and it will definitely attract customers with its compatibility to standard M3 bolts. Also we expect Terence Tam, the man behind OpenBeam, to come up with other products and manuals.

Now there is a kickstarter campaign for Makeblock. Makeblock offers just about everything. They are good and their goal is to add even more new components. A small production run took place for most of the parts. For these parts Makeblock is looking to start mass production. They are kickstarting from a different point.

Their goal is to provide a full range of solutions. It looks like they are fully equipped to do so. Makeblock looks more finished. Lego is often used in reference to open source hardware. It provides a recognizable standard. Makeblock gives the feeling of being the aluminum lego version. Absolutely wonderful and very appealing but not sure whether it will suit everyone.

Kickstarter campaigns open source hardware

|

Backers |

Goal |

Pledged |

Time |

| MakerBeam |

132 |

10,000 |

17,922 |

September 2009 |

| OpenBeam |

534 |

30,000 |

100,825 |

March 2012 |

| Makeblock |

192 |

30,000 |

104,453 (closes end of January 2013) |

December 2012 |

In the 2009 MakerBeam kickstarter campaign it is mentioned that MakerBeam is thought to be the first open source construction set made available through crowdfunding. It is not enough to run a good Kickstarter campaign. The product needs to be available to customers as well. Things went quiet around MakerBeam for a long time. By making it available people start working with makerbeams and new components or 3D printed designs are being developed.

Makeblock and OpenBeam make better use of their kickstarter campaigns. The open source hardware community is benefiting from this.

It is a great time to be a maker!

Team MakerBeam.eu

With a very special thanks to Low-Tech Magazine and its article titled: How to Make Everything Ourselves: Open Modular Hardware